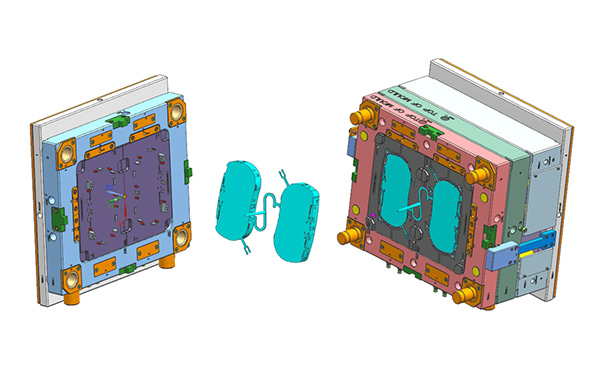

Why Automotive Manufacturers Choose RYD Tooling

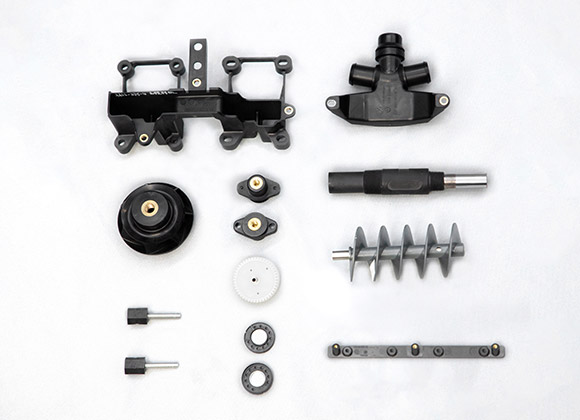

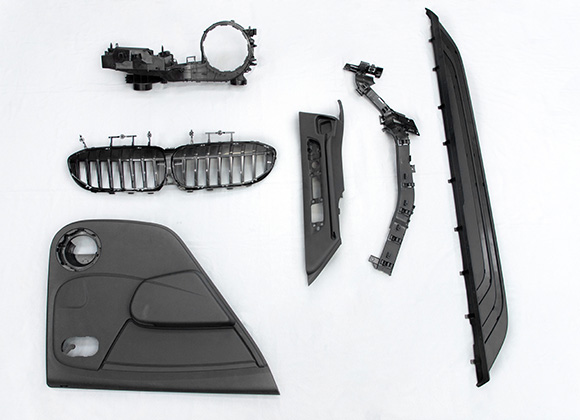

Flexible customization

RYD Tooling can produce a variety of automotive parts regardless of the vehicle design. ODM and OEM services are available.

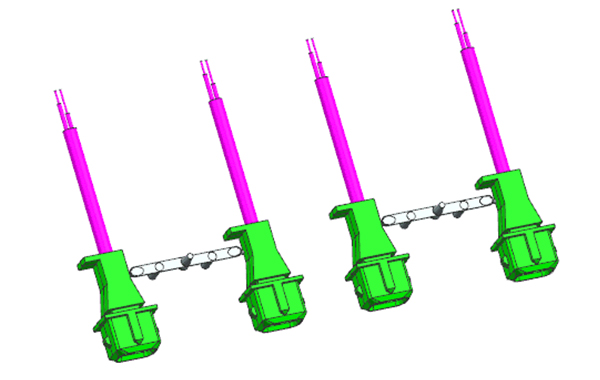

On time and on budget

We help control costs and create a timetable for your project, taking full advantage of our supply chain network and injection molding capabilities.

Reliable and safe parts

We use engineering-grade resins sourced from reliable suppliers and have the production process under stringent quality control.

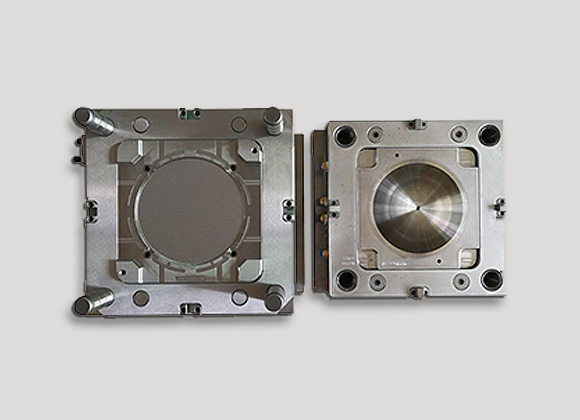

High accuracy and fine detail

Perfect combination of advanced machines and specialized techniques guarantees the car part is built to your exact requirements.