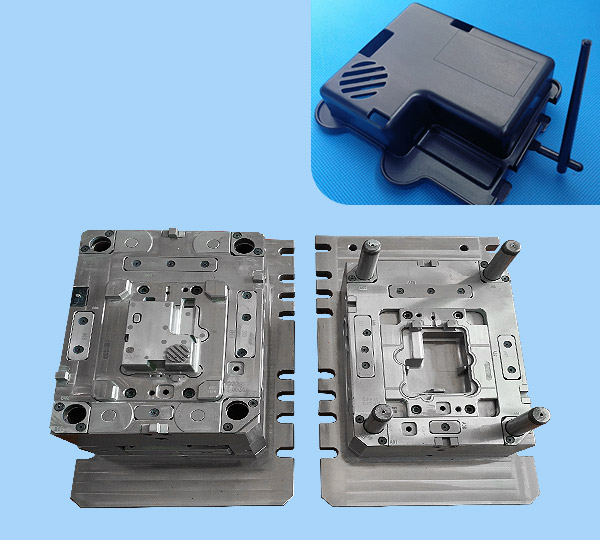

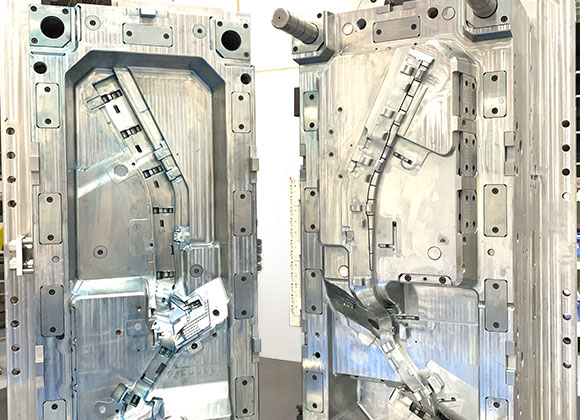

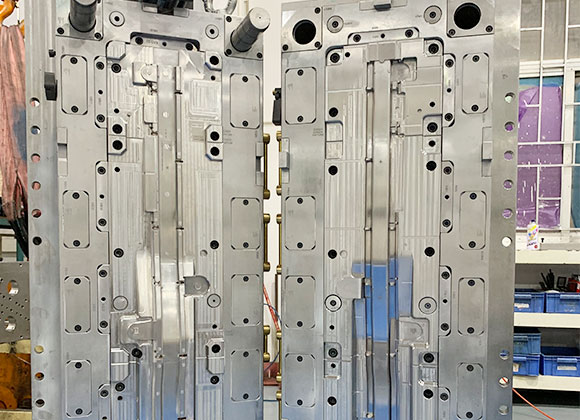

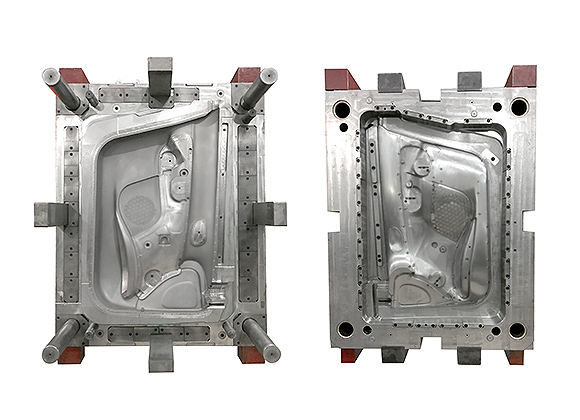

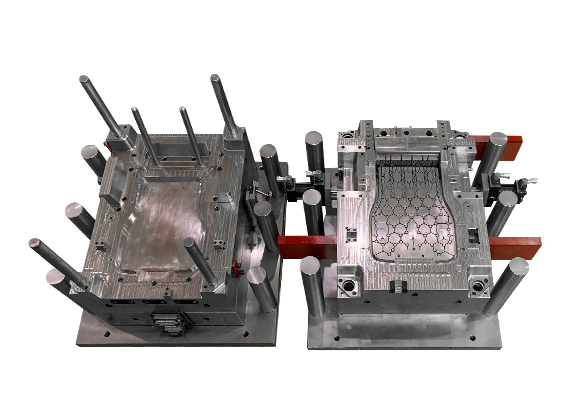

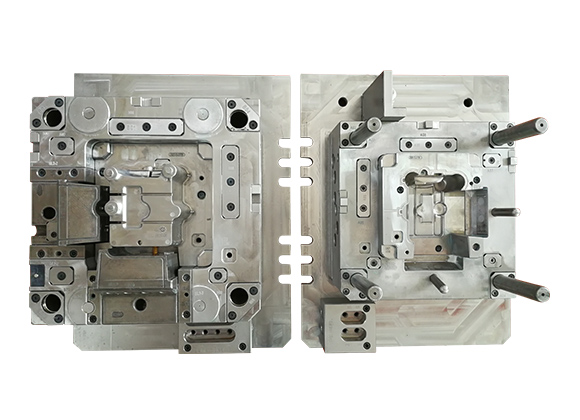

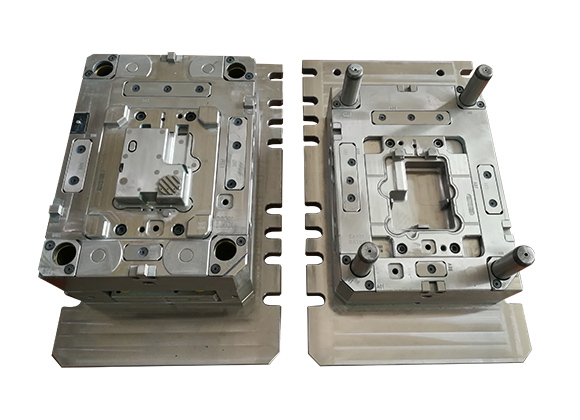

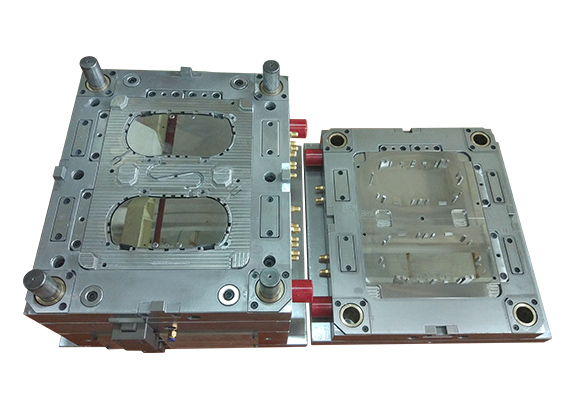

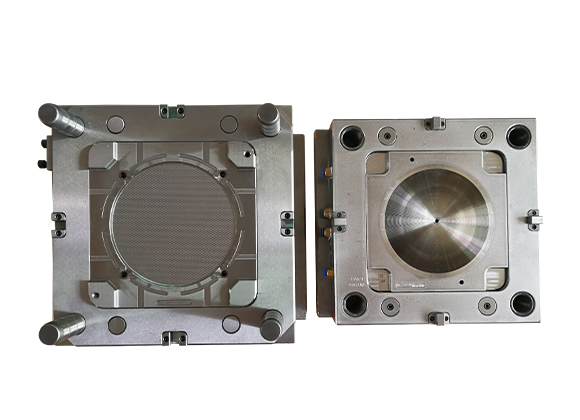

Any injection molding component is only as good as its raw materials. At RYDTOOLING, we use only the highest quality engineering-grade thermoplastics, resins, and other raw materials that ensure our end products are durable and functional. Our products go through rigorous quality tests at all stages of manufacturing to make sure there are no errors in precision.

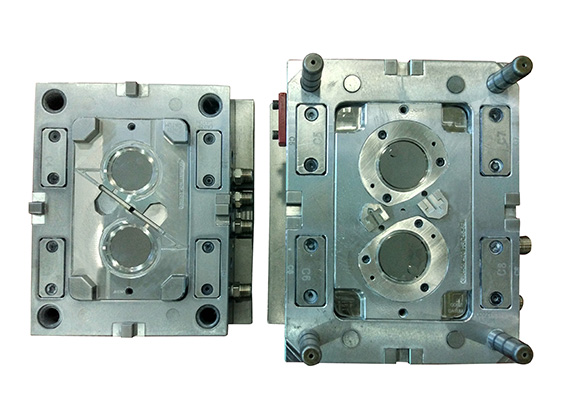

Optimized product size and weight