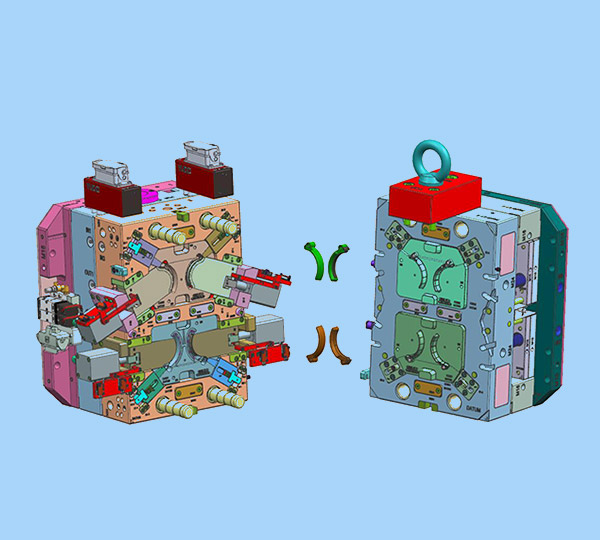

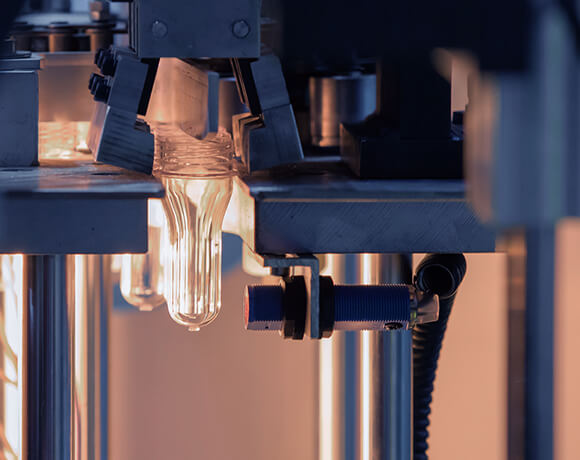

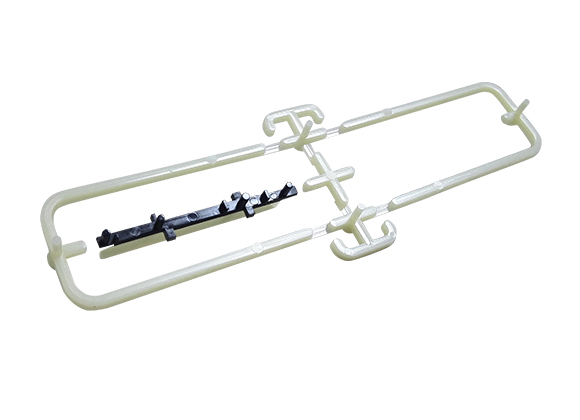

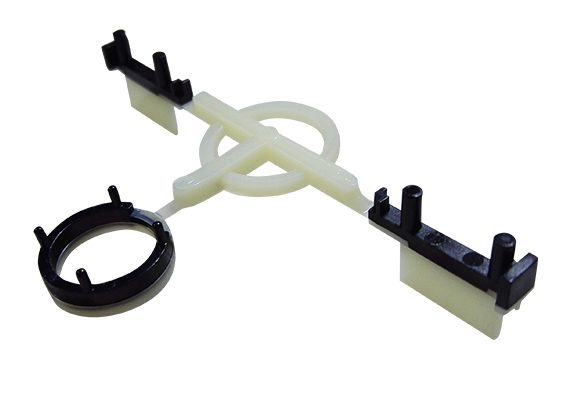

Two shot injection molding is an efficient way to produce custom plastic parts with two or more plastic resins or colors in one operation to achieve a specific function. The process is also referred to as transfer molding, 2k molding, two-color injection molding, multi-color injection molding, 2-component injection molding, and the like.