-

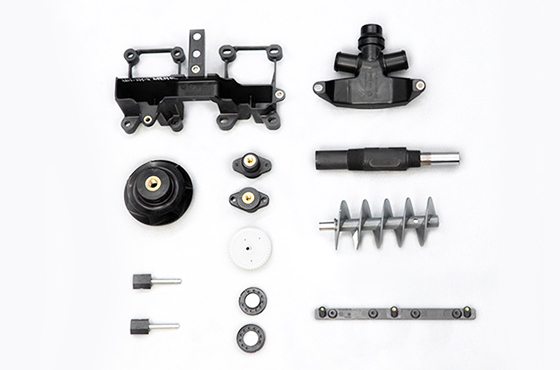

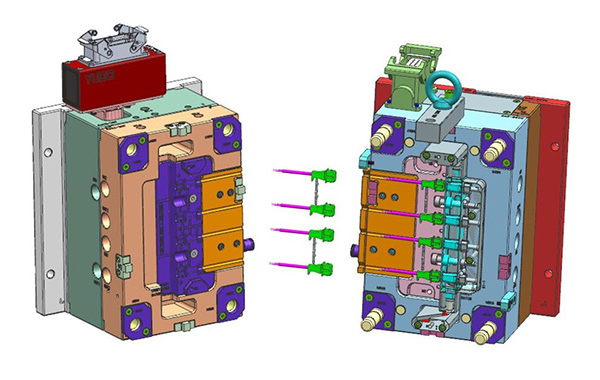

High precision

By thorough analysis and practical design, we engineer and build custom injection molds and plastic products to your exact specifications.

-

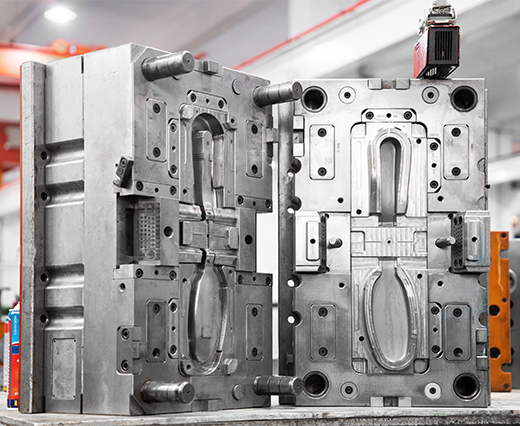

High performance

Reliable steels and resins ensure the mold’s durability while its well-designed and engineered mechanism guarantees its functionality.

-

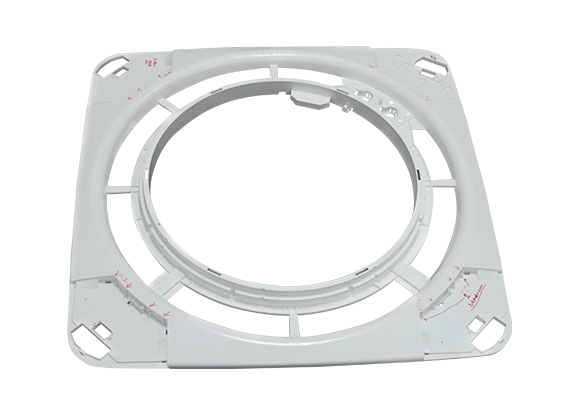

Increased profitability

Our team of injection mold experts always delivers measurable results through systematic approach to improved quality and a reduced cost.

-

Exquisite details

We use specialized techniques to meet any of your specific requirements about tolerance and low defect chances.

Hear What Our Customer Says

-

Cristian from Germany

Thank you for your support. To be honest, yesterday evening I was very confused and upset about the status of the project, especially about missing 3D models of the molds. Today, in the morning, when I saw the 3D models, I had a really positive surprise. Thank you for the efforts of RYD Team. I really appreciated.

-

Igor from Canada

Crank handle and Lid—Sample Report--R623-2 Thanks Young…by the way – amazing job. It’s great to have a partner like you on this.