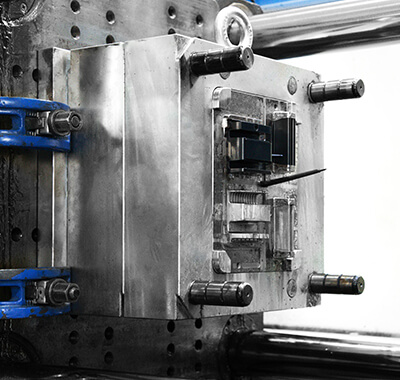

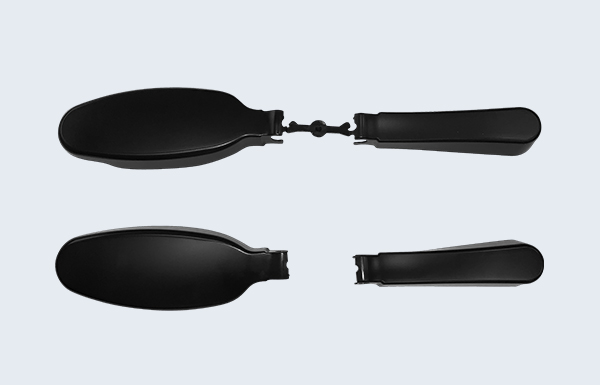

Efficient Processing Cycle

Short processing cycle ensures high efficiency and productivity. Each cycle takes up typically between 2 seconds and 2 minutes, consisting of 4 steps: clamping, injection, cooling, and ejection. When the injection molding cycle and some post processing (when required) are finished, some types of material like thermoplastics will be recycled as a method of Lean Manufacturing.