Initial Analysis

We offer professional part and mold design services to injection mold manufacturers, injection molding factories, design companies, and product developers. To create an ideal injection molding solution for you, necessary information should be provided for us to perform an initial analysis, such as:

- · Purpose: you wish us to improve an existing design, create a new one, or OEM according to your drawing;

- · Approach: you can send us a drawing, or a sample product for us to restore the design;

- · Other details: desired production volume, expected application, preferred material, productivity of your injection molding machines and so on.

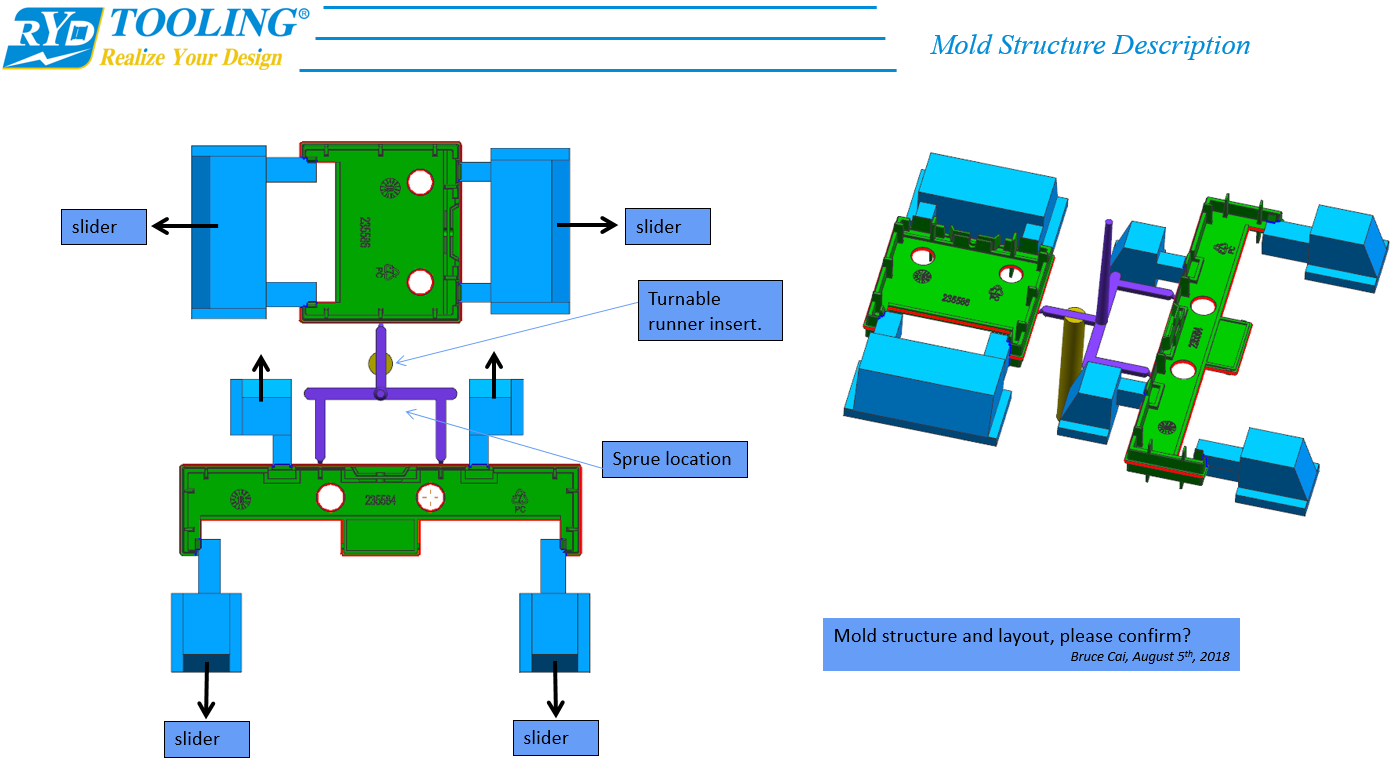

Design For Manufacturing

RYD Tooling performs a manufacturability analysis on each injection molding project to optimize part design, minimize tooling costs, and reduce overall project time. The detailed analysis report is reviewed by the lead designer, toolmaker, injection molding engineer, and project manager to ensure the requested component is appropriate for injection molding. From the report we will show you:

- · Proposal for gate

- · Proposal for parting line

- · Mold structure (& material)

- · Ejection solution

- · Surface treatment

- · Other proposals (part thickness analysis, draft angle analysis...)

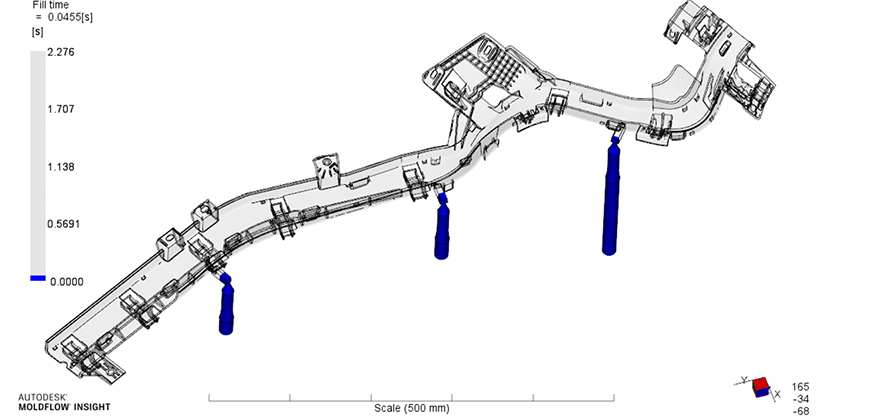

Mold Flow Analysis

RYD Tooling offers Mold Flow Analysis service to ensure that underlying manufacturing problems are highlighted and detected during the design phase as guidance for improving the design. If you would like mold flow analysis for your tool please inquire in advance because additional charges may apply. Subjects of a mold flow analysis report usually include:

- · Analysis Model

- · Material

- · Runner System

- · Cooling System

- · Process Settings

- · Filling Pattern, etc.

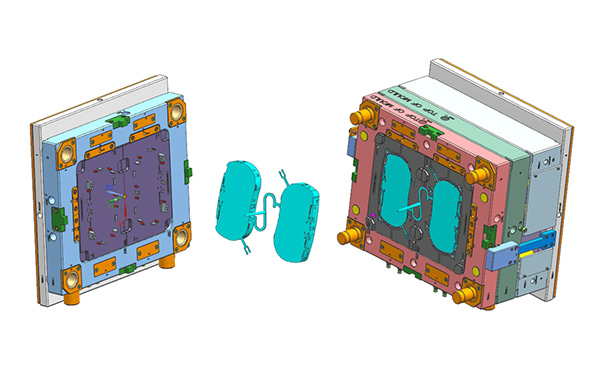

Part & Mold Design

We have a qualified team of designers and engineers that bring together innovation, technology and experience to solve the challenges of turning an entirely new product, concept or idea into a marketable solution. From the design phase, our design team will provide:

- · Industrial design

- · Appearance design

- · Structure design

- · Mold design (2D & 3D)

- · Material selection

- · Cost estimate