-

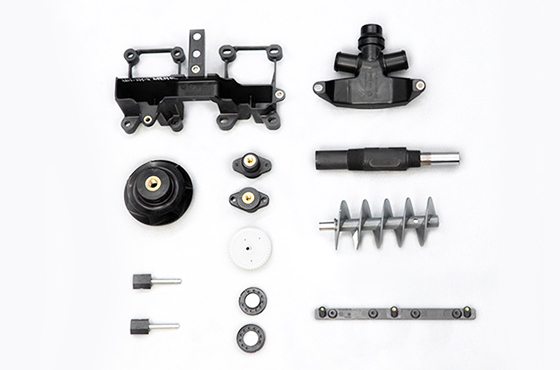

High degree of design freedom

With rich expertise and comprehensive analysis and testing, we can design and build plastic electronics components to any special requirements.

-

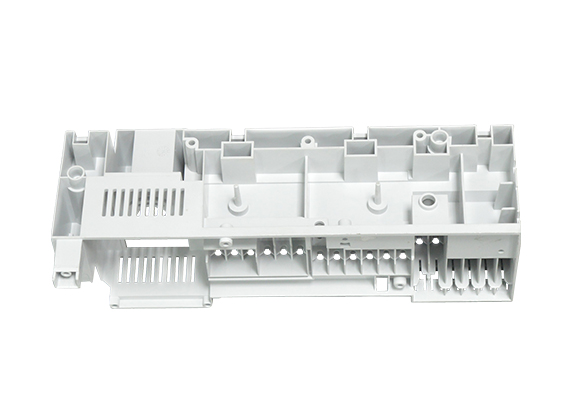

Advanced physical properties

We use high-performance and engineering-grade resins to offer extreme temperature resistance, chemical resistance, enhanced load bearing, and other features.

-

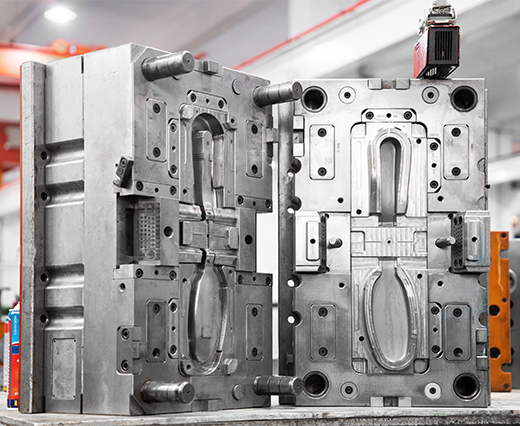

Shorter assembly times

We use efficient processing methods and techniques, as well as top-notch equipment, to guarantee quality and high productivity.

-

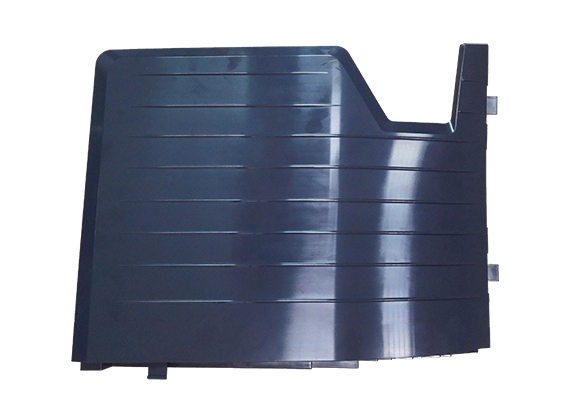

Lower total costs

All RYD tools and production parts are made under one roof in our China-based factory, which eliminates the costs related to a third party.