Your Reliable Injection Molding Manufacturer

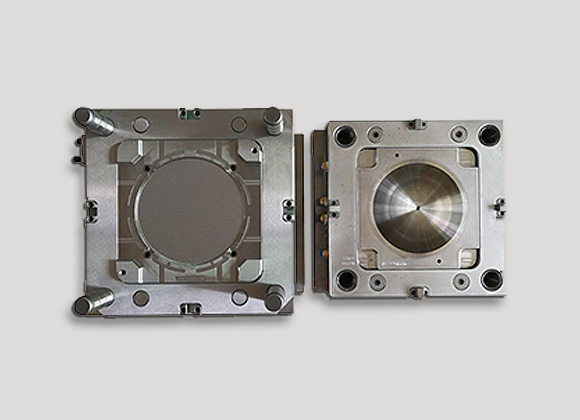

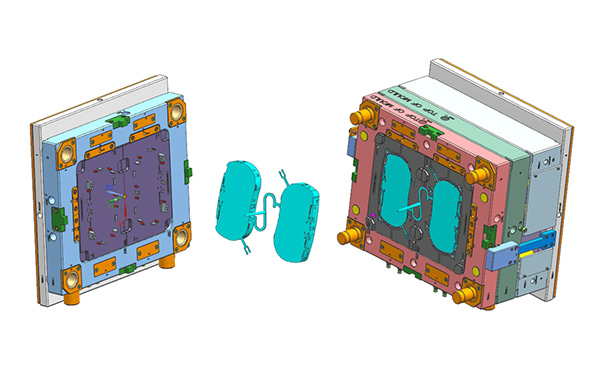

Do you need precise injection molds or plastic injection molding services? RYD Tooling has the right solutions for your project.

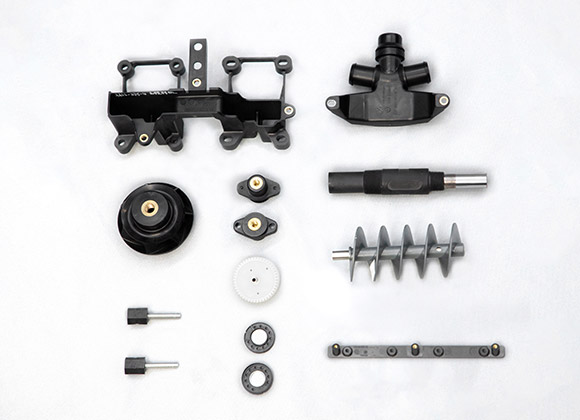

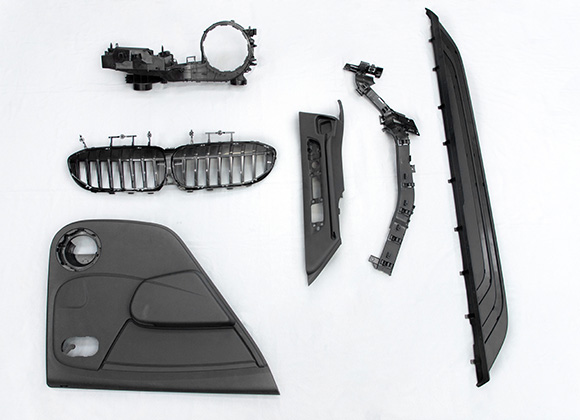

We are a reputable injection molding manufacturer that offers design, prototyping, and injection molding services. We use premium quality materials to ensure we deliver durable products with high functionality.

Have a custom design concept in mind? No problem. Simply send it to us and we will implement it to perfection.

-

Competitive Pricing

at least 15% reduced cost

-

Quality Assurance

High precision, feasible design.

-

Short Lead Time

2 times faster than foreign competitors