Our customer from Australia obtained a project from the local government to develop a traffic light lens. This special les is called Fresnel Lenses which has lots of saw-tooth feature. RYD has never made such a product before, but we are going to look for the solution. We have seen similar traffic light on the street, we are sure that it is made by injection molding. The critical point is that how to make the saw-tooth feature on the lens.

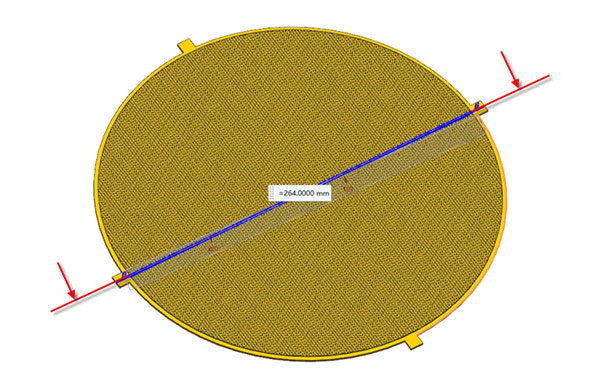

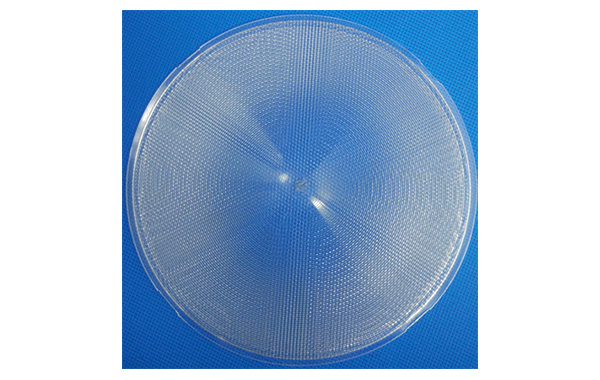

1. This Fresnel lenses is quite big, diameter 264 mm. Surface treatment requires 60 to 100 nm in lighting level.

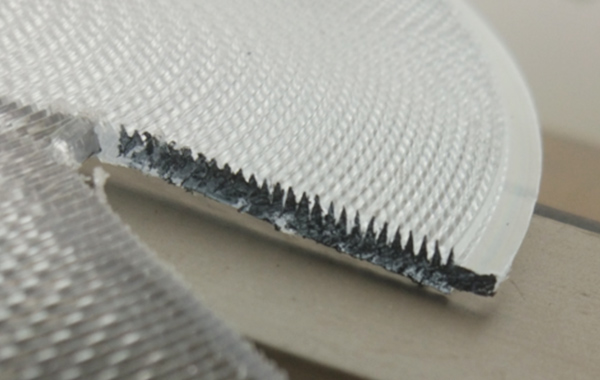

2. As the section view shows, the conventional processing method can not make it, processes include the high-speed precision CNC machining, and the EDM discharging.

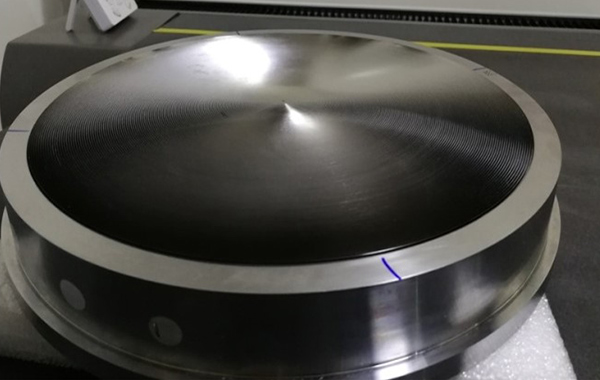

We see some LED lenses also have the similar saw-tooth features, after consulting the experts who have made such lenses and evaluated, we decided to use the process electroforming. In Shenzhen or in China, there is less manufacturers who can do the electroforming, and the cost is way high. We found the manufacturer who can actually do the electroforming with a reasonable price. This is not an easy project, one of the reason is that the lens is large and it’s normal that if they couldn’t make it with just one trial. Honestly, we had tried 3 times to complete the whole mold insert with the saw-tooth feature, same as the lens design drawing.

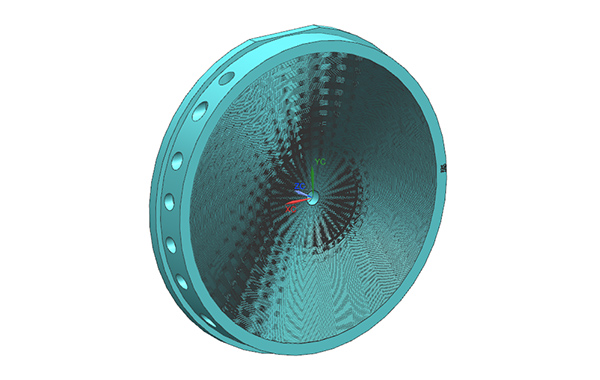

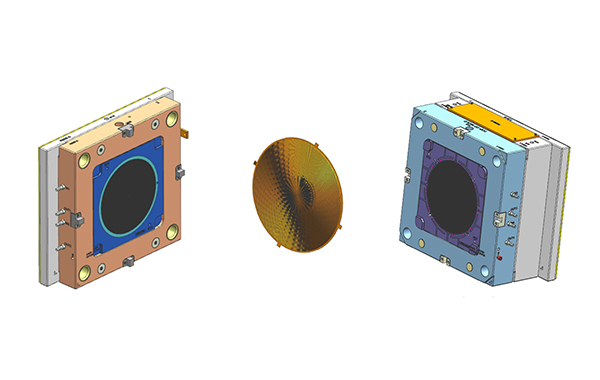

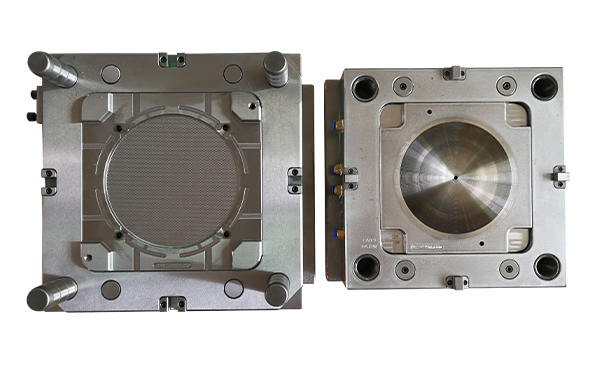

This is the mold design drawing, there is no complicated structure. As long as the saw-tooth feature are resolved, other things are not difficult.

Specification:

Part Name: Fresnel Lens

Part Material: PC

Mold Cavities: 1 Cavities

Steel of Cavity/Core: ASSAB S136H

Mold Life: 5.00,000

Mold Dimension: 500*600*383 mm

Standard Parts: HASCO Metric

Polishing Grade: 60-100 nm Lighting Grade

Ejection: Standard Ejection

We didn’t do the mold flow analysis this time, but we made the great mold with great injection molding parts, the T1 samples got the approval from our customer.

Hi Bruce and Young,

I am glad to tell you that the lens has passed the test, thank you for your effort, the team of RYD did a great job. We also have more to develop, will send you the RFQ.

Thanks.

Peter