As a business relying on plastics for packaging different products, it is important to ensure that you get the best options in the market. This will ensure that you provide your users with quality options that will last them a long time. The best way to get quality plastics to work with is by relying on plastic molding as your primary manufacturing method. For this, you need to get a plastic injection molding manufacturer that you can work with. The demand for plastics that are molded into different shapes and designs is quickly gaining momentum. This is mainly because it is more cost-effective for businesses rather than working with other materials.

Source: www.ien.com

Molding is used to refer to a process that involves the use of a mold to shape a liquid or pliable material into a desired shape or form. Plastic molding involves the use of powder or liquid polymer that is inserted into a hollow mold. Once the polymer is inserted into the mold, it then takes on its shape depending on the specific mold you’ll be using. To make this process more efficient, you can incorporate the use of heat and added pressure. This will result in a better and more defined end product once you are done with the molding process.

When it comes to the specific of how much heat or pressure to apply, you’ll have to work with the specifications of the plastic molding process you’ll be using. There are different plastic molding processes that can be applied to get a quality end product.

Source: predictabledesigns.com

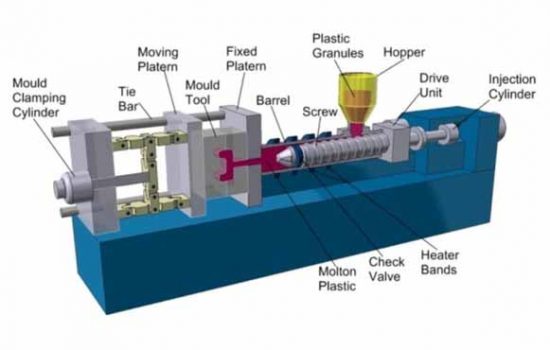

When it comes to injection molding, there are a few different aspects you need to consider to make this process a success. This process will require the use of an injection molding machine, raw plastic materials, and a mold.

The injection molding process undergoes a cycle that ensures all the products are well molded and of great quality. This cycle involves:

Before the molten plastic material is injected, the mold has to be well secured. For this, the injection molding machine comes with a clamping unit designed to keep the mold secure. One side of the clamp is designed to be stationary while the other can move back and forth to facilitate the insertion and removal of the mold. Once the mold is in place, the clamping unit that is allowed to move will press into the mold aiming to attach back to the other clamping side. Once this is done, the mold is secure and the process can begin.

Injection

Once the mold is secure, you’ll feed in the plastic material that usually comes in the form of small pellets. This material is fed in using the injection unit that comes attached to the machine. During this process, the plastic pellets are melted by heat and pressure that is applied. Once it’s molten it is then immediately transferred into the mold and held there to ensure it accurately takes shape.

Cooling

After the molten material is injected into the mold, it begins to cool and solidifies and takes the shape of the mold being used. During this process, there may be a bit of shrinkage that is addressed by the molten substance continuously being directed into the mold to make up.

Ejection

After sufficient time has gone by and the cooling process is complete, the cooled part can then be ejected from the mold. The ejection system comes in handy and pushes out the solidified material from the mold.

Source: www.chukoh.com

Some of the products that are made from injection molding include:

With the application of injection molding, you’ll find that plastic bottles are the most common products manufactured. They feature the use of polyethylene terephthalate, a material that is light and strong suitable for consumer water bottles. With injection molding, the bottles are designed in different sizes and shapes.

When it comes to different electronic requirements, you find most manufacturers prefer fabricating all their housing using the injection molding process. The housings are made of plastic and are designed to feature great quality. Some of the housing made include those used for remote controls, computers, and sockets among others.

Different companies are using the injection molding process to manufacture quality toys for their consumers. For instance, the lego toys are well designed and go through the injection molding process from start to finish. They are accurately designed to feature different colors, sizes, and shapes that fit each other perfectly.

Source: Wikipedia

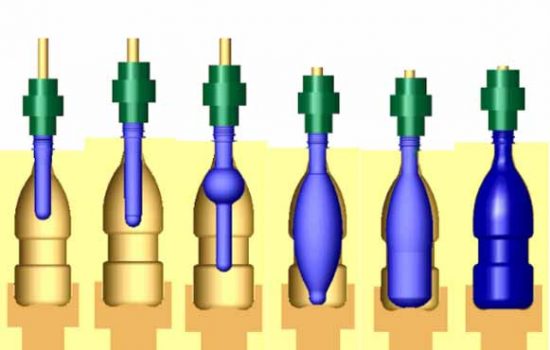

Blow Molding is featured when it comes to the manufacture of hollow plastic products. This is a great process to consider especially if you need to feature different thicknesses in the end products. This process includes the use of molten plastic material and compressed air. Once the plastic material is completely heated, to its melting point, it is transferred into the cavity of a mold. The mold is designed in the shape and size of the product you want to work with.

Once the molten material is in the mold, compressed air is then used to inflate the material like a balloon. This allows the plastic material to take the shape of the mold and still remain hollow. When it comes to the thickness of the end product, this will be dependent on the amount of molten material you include in your mold. When it comes to working with blow molding, some of the factors that affect this process include the temperature used in melting the plastic material, inflation pressure, blowing speed, inflation ratio, and temperature of the blow mold.

Source: valenciaplastics.com

Some of the products featured in blow molding include:

Different gardening products will feature the use of the blow molding process. These are gardening pots, watering cans, and garden decorations among others. They are made of plastic and require the hollow feature that is well executed by this method.

In some situations, to achieve the ergonomics that are required for efficient and quality office chairs, blow molding is required. Given that with industrial application blow molding can achieve any given shape, the process works well for this purpose.

Plastic wheels are mostly made using the blow molding process and designed to be very efficient. They are featured in different toys and other applications in different areas of our lives. This option makes them very economical and also customizable.

Source: www.engineeringclicks.com

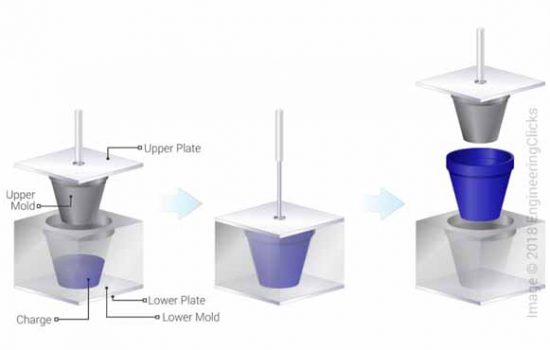

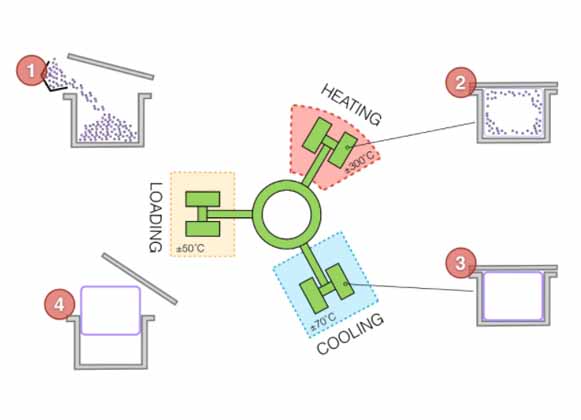

Compression molding is a three-dimensional object-making process that requires the use of a heated and pressurized plastic polymer material. The upper compression part and the lower compression part make up the compression molding unit. The lower part is fixed to the ground, while the upper part can be flipped over using the guide pins. A heating and cooling system is mounted in the lower part of the system. Compression molding involves first heating the plastic polymer that is usually in granular or pellet plastics then placing it into the cavity of a mold. Afterwards you can use a plug to cover the top of the mold. Once this is done, the molten polymer gets pressurized. This allows for it to expand and fill the cavity of the mold with ease.

Compression molding is a highly efficient molding process in the manufacturing industry because it combines both pressure and heat. Compression molding, like other molding methods, is affected by a variety of factors. For example, if the plastic polymer isn’t heated to the right temperature, it can fail to fill the mold cavity. On the other side, if the plastic polymer is overheated, it will produce an unnecessary amount of pressure and necessitate a longer cooling period.

Source: plantech.com

From plates to cups, different kitchenware will feature the use of the compression molding process. The products are compressed into shape and feature a strong quality material. Compression molding gives the best translation in terms of the results and accuracy experienced.

Different electrical housings are designed and produced using the compression molding method. They are designed to house different electrical elements like remote controls and important electricals.

Switches feature the use of plastic material that is compressed to take the shape of the exact switch required.

Source: slideplayer.com

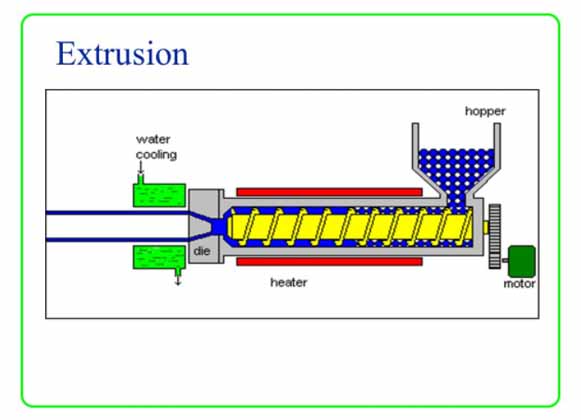

In the extrusion molding process, raw thermoplastic material, or resin, is gravity fed into the barrel of an extruder from a top-mounted hopper. A hooping container is used to insert and combine the plastic powders in the plastic extrusion machine. The chemical materials are first mixed inside the barrel by the screw conveyor. As with the other molding machines, the temperature is normal. Second, the heater keeps heating the plastic until the plastic extruder successfully inserts the wire into it.

Colorants and UV inhibitors, in liquid or pellet form, are commonly used and can be inserted into the resin until it enters the hopper. The material comes into contact with the screw on reaching the feed throat near the rear of the barrel. The plastic resin is forced forward into the barrel by the spinning screw, which is heated to the ideal melt temperature for the resin.

Source: paulmurphyplastics.com

PVC pipes are created using the extrusion molding method and are designed to be strong and offer great value. When it comes to working with industrial products and chemicals that need to be transported with pipes, PVC will be substituted for a different material.

Impact-resistant polycarbonate sheeting is used in window glazing and machine guards. It comes in a variety of thicknesses, from thin films to several inches thick. Acrylic plastics are also extruded into thin sheets that can be used as glass substitutes.

When it comes to achieving long cross-sectional shapes that actually provide quality results, the extrusion molding method is a great process to consider. Windshields are made using this process and are designed to be efficient and offer great performance.

Source: www.pentasmoulding.com

When it comes to this type of molding, powdered plastic material is inserted into a hollow mold, which is typically made of cast aluminum or manufactured from sheet steel. The mold is closed and slowly rotated on two axes. The polymer eventually melts and sits on the inside of the mold as it is heated in an oven while spinning. The mold is transferred to a cooling station and cooled with air and often a fine mist of water until the polymer powder has completely melted. The part solidifies as the mold cools.

The process is stopped and the product is taken out of the mold until the material has cooled enough to release it from the mold surface. When it comes to the different factors that may affect this process, you can expect to consider a few things. Many factors may influence production and the final product, including ambient temperature and humidity, mold form, material specifications, and powder quality.

Source: www.egoplastic.com

Bulk containers and plastic bins can be made in a variety of styles, colors, and sizes using rotational molding, all for the purpose of storing and shipping items in a simple and convenient manner. In the food processing and material handling industries, these bulk containers come in handy.

Rotational molding can be used to make a wide variety of sporting equipment, including dumbbells, playground equipment, helmets, and golf carts, in addition to water sports essentials including kayaks and canoes.

Storage tanks for agricultural, commercial, and industrial purposes are often widely made using rotational molding. These tanks can vary in size from five gallons to 22,000 gallons thanks to the versatility of rotational molding.

If you are looking to diversify your manufacturing process and incorporate plastic molding, take your time to work with a tooling manufacturer. This will give you the best advantage and ensure that you invest in quality. A plastic molding manufacturer will help you create different variations of products depending on what you are in the market for. This is made possible by the different types of plastic molding that you can consider. Take your time to learn more about the different processes and the products they are used for. This will help inform your decision and give you a better chance at getting the best results.

+86-755-8524 1121

marketing@rydtooling.com

No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China. Post Code 518105.

Subscribe to our newsletter to get manufacturing news and updates!