There are different types of plastics developed using different processes. Over the years more people have continued to embrace the use of plastics as alternatives for different applications. With this, the technologies have changed and they feature different types. To get the best, work with a qualified tooling manufacturer and get to know about you these products and processes. Learning more about thermoset and thermoplastic plastics will be a great advantage. It will allow you to determine what works best and invest in that.

Source: lisongmachine.medium.com

We feature the use of plastics in different parts of our lives with a vast range of applications. This goes to show that plastics are more preferred for different reasons. They are a great option given the fact that they always get the job done. You can easily rely on your plastic from the keyboard you use down to your favorite pen. When it comes to thermoset plastics, they are unique and are different from the traditional plastics we are used to. These plastics are designed to withstand high heat and do not disintegrate and melt when heat is introduced.

On the contrary, these plastics are made by first being exposed to excess heat. Both the physical and chemical states of these plastics are set using high heat to ensure that they are of great quality. With this, you find that the plastics are no longer affected by any heat exposure. The ability of these plastic materials to withstand and have resistance towards corrosion and heat makes them suitable for certain applications.

The thermoset plastics are best used in places that require tight tolerances and strength. This is because they exhibit high pressures from the heat being applied. When it comes to the production of these thermoset plastics in bulk, it becomes easier. This is because the process is quite easy and features the use of a selection of raw materials at an affordable rate. Additionally, the process is designed to feature accuracy and efficiency at every stage.

Source: pt.slideshare.net

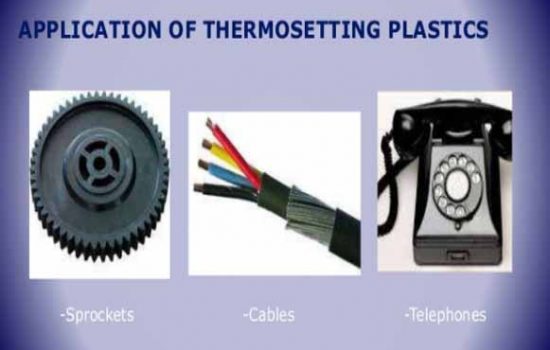

Given that these plastics are designed to withstand a great deal of pressure and exhibit massive strength, they can be used in very unique applications. Thermoset plastics exhibit enhanced thermal stability, structural integrity, and chemical resistance that make them work with accuracy when in application. This helps improve their performance compared to other alternatives. When it comes to the use of thermoset plastics, they are used in various industries with numerous applications. Some of the industries that feature the use of thermostat plastics include electrical, lighting, energy, automotive, and appliances among others.

Source: medium.com

Thermoset plastics feature different applications suitable for different industries. Additionally, these plastics come with added advantages that you need to take into consideration and capitalize on. Some of these advantages include:

As discussed earlier, thermoset plastics are created by being subjected to heat and formed into strong durable plastic materials. Once they are subjected to heat, they are no longer affected by it even after being fully formed. This is a big advantage given that they get to be used in applications where the use of heat is featured. These plastics are designed to withstand pressure without causing any issues on the application.

Compared to the metal alternatives the thermoset plastics are cheaper. They come with an initial investment that is significantly low. This makes it an amazing option that you can consider.

Thermoset plastics can easily be used and manufactured in different colors to add diversity and character depending on what you are looking for. You can either feature a shiny or matte finish among other different options. This makes the thermoset an amazing investment.

The thermoset plastic is created and designed to feature high performance in all its applications. This makes them a great option to consider when looking for the perfect plastic option for your projects.

Thermoset plastic also features the ability to resist any corrosion and effects that may be caused by getting into contact with water. This makes it an amazing option to consider when choosing your desired form of plastic.

Source: www.opusplastics.com

Like any other product, thermoset plastics also feature a few disadvantages that you need to keep in mind. Some of them include:

Given that they are shaped with the use of heat, they become resistant to any adverse heat effects after they are fully formed. This makes them harder to reshape. Reshaping and remolding are impossible given that there is no way to melt or disassemble the thermoset plastic.

The thermoset plastics cannot be recycled or reused. This becomes a problem for those keen to conserving the environment.

Source: revpart.com

When it comes to working with recyclable and versatile plastics, this is the perfect choice to consider. For the thermoplastic Polymers to form, there needs to be repeating units called monikers linking into chains and branches. This is what helps the formations of this particular plastic. When subjected to heat, the thermoplastic pellets soften and melt as the heat is increasingly administered. With this particular plastic, the shape and form created are completely reversible. This is because the formation process doesn’t feature any chemical bonding. This allows it to be easily removed and reshaped with ease. It also facilitates recyclability without negatively affecting the material’s physical properties. This particular form of plastic uses different types of resins that may feature different advantages in the application.

Source: insights.globalspec.com

Steel piping systems are susceptible to rust or corrosion in dirty, acidic conditions such as those found in modern cities, and thus require special corrosion protection. The cost of shielding steel piping systems that are exposed to these harsh environments can be quite high. This is why thermoplastics are preferred because they offer better rates and can get the job done as well.

Common materials used to produce these pipes are PVC or CPVC. Additional materials include polypropylene, PVDF, ABS, nylon, and polyethylene. Polyethylene gas tanks are used to transport natural gas for use in residential and commercial applications. With the variety of applications featured, you find that most people are drawn to using these particular plastics. They are quite easy to use and offer great versatility both in industrial and domestic spaces.

Source: www.lomont.com

When it comes to using thermoplastic plastics, there are a few advantages that you need to pay attention to. These advantages include:

If you are a keen observer of the effects you have on the environment, these plastics are the best option for you. They are designed to be recyclable and reusable seeing as they feature the use of incredible materials.

When subjected to heat these plastics melt, and can easily be molded and reshaped. This allows you to convert them from one shape to another and potentially change their application.

This particular plastic features the use of injection molding and may feature numerous grade finishes. You can achieve different looks with thermoplastics compared to the thermoset when it comes to working with surface finishes.

They are quite easy to manufacture and can be done in large scale. This makes them readily available and easy to work with.

Source: shuman-plastics.com

There are different shortcomings when it comes to using any plastic-type or material. When it comes to thermoplastic plastic, here are the cons to keep in mind.

With a low melting point, it becomes easier for materials to disintegrate under the slightest indication of heat. This hinders the performance of this plastic greatly. If installed in a place exposed to direct light and heat from the sun it would melt. This will disrupt the application and function of the plastic products.

Thermoplastic plastics may be more expensive given the fact that they are not as long-lasting and strong as the thermoset. This gives it a big disadvantage for people looking for an affordable option.

There’s a huge difference between thermoset plastics and thermoplastic plastic. In terms of performance strength and even how they are manufactured. However, when it comes to which is better, they are both useful in the different industries they serve. Determine what you want, work with a tooling manufacturer to get you started, and create the products you need.

+86-755-8524 1121

marketing@rydtooling.com

No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China. Post Code 518105.

Subscribe to our newsletter to get manufacturing news and updates!