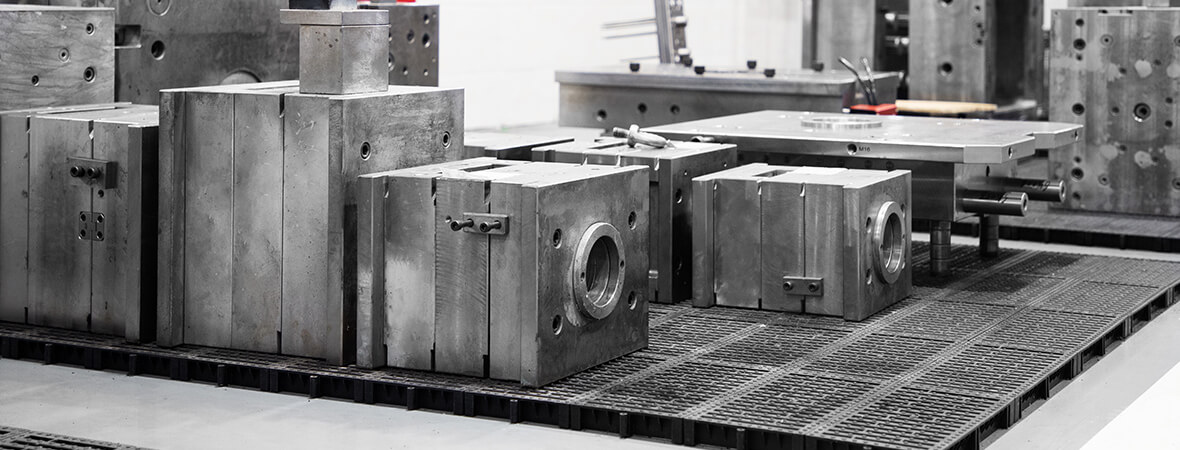

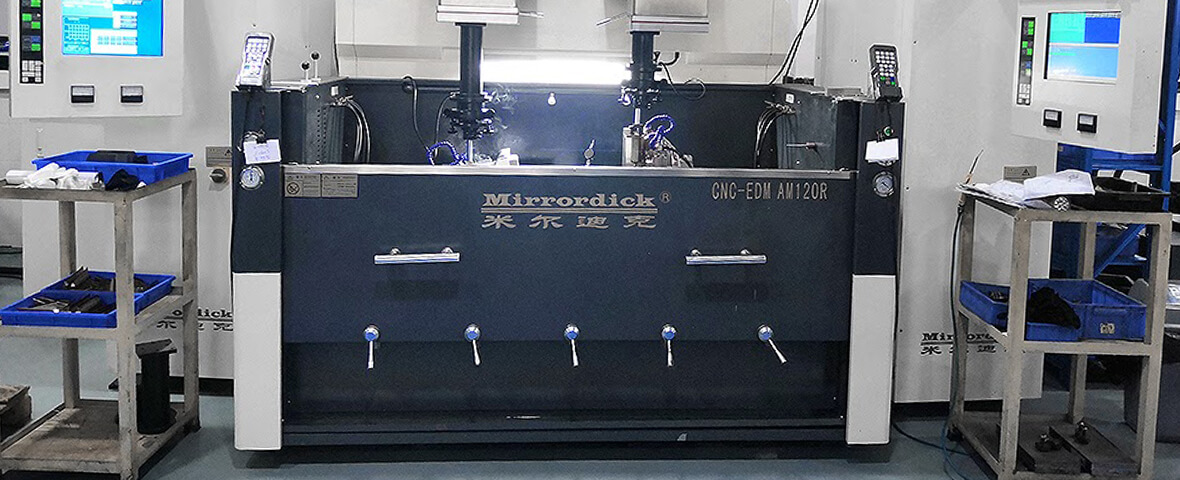

Advanced Machining Capabilities

Using the latest in technological equipment (EDM, multi axis CNC, and plastic injection molding machines), we are able to produce an injection mold with high quality and tight tolerance from simple to sophisticated design. Molds and parts produced by us have brought satisfaction to many clients from different industries like automotive, household appliances, electronic, furniture, aerospace, and other industrial markets.