The injection stretch blow molding process is one of the major methods in blow molding that is used in the manufacturing of hollow objects by the use of polymers with rotational symmetry. It is mostly used for the production of high-quality containers.

The type of material that is used in this process is:

Polyethylene-terephthalate: This is also known as PET. It is the chemical name of polyester. It is a lightweight plastic, but also strong at the same time. It is mainly used for the packaging of foods and beverages.

Rapid injection molding prototyping is used for the production of thermoplastic resin in weeks.

Overview of the Process

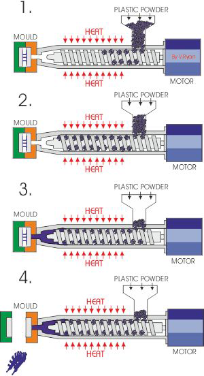

The process is divided into four parts:

- Injection

- Stretching

- Blowing

- Discharge

Injection

After the polymer is melted, it flows into the injection cavity. This then takes the desired shape of the preform using the injection molding process. Here, the mandrel produces the inner diameter, and the inner cavity makes the outer diameter. After a certain amount of assigned time, the preform held in the neck carrier is rotated by 90 degrees.

Stretching

During this part of the process, the preform is heated up to a certain level and then given a final shape. Another point that needs to be kept in mind is that due to this constant heating, the elasticity is not high. The stretching forms void too. At a stretching ratio of 3:1, effect pigment can be used.

Blowing

Blowing and stretching work hand-in-hand, if we may say. The preform is correspondingly blown and stretched to its final alignment. As the preform comes inside the blow mold, the mould area closes. The stretch rod inside, stretches it longitudinally and thus the stretching part of the process is also performed.

Discharge

As the name of the process suggests, this is where we get the final product by discharging. After a certain amount of assigned time, that is given for cooling, the molds open. The preform is then removed carefully with the help of drop chutes or robotics.

Benefits of Injection Stretch Blow Molding Process

Since it is a combination of injection molding and blow molding, we can infer that the benefits will be manifold.

These are:

- Efficient process

- Dimensionally accurate

- Excellent strength

- Reduce weight containers

- Ensure resistance

- O2 and CO2 barrier

- Low mold cost

- Crystal clear containers

- Reusable preform

Efficient Process

The injection stretch blow molding process is very efficient in comparison to other processes. The speed, in this regard, is also better.

Dimensionally Accurate

As the neck finish is dimensionally accurate, it also leads to preciseness in the product and its application.

Excellent Strength

This process, as is the amalgamation of two other processes, gives great strength to the finished products. The overall strength to weight ratio is excellent.

Reduces Weight Containers

This process helps in the reduction of the weight of the containers.

Ensures Resistance

This process makes the finished product durable and makes it prone to high resistance.

O2 and CO2 Barrier

The bottles that are manufactured provide excellent barriers from O2 and CO2.

Low Mold Cost

While this process undergoes, the mold that is used does not burn the pocket as much as that happens during other processes.

Crystal Clear Containers

Crystal clear containers that are made using the injection stretch blow molding process helps in giving a better view of the actual product and are also lightweight which is better than glass products manufactured using other methods.

Reusable preform

In the injection stretch blow molding process, the preform is reusable and can be made into various shapes for attaining different products.

Categories of Injection Molding

Injection molding is divided into some categories. Here, we will discuss two-

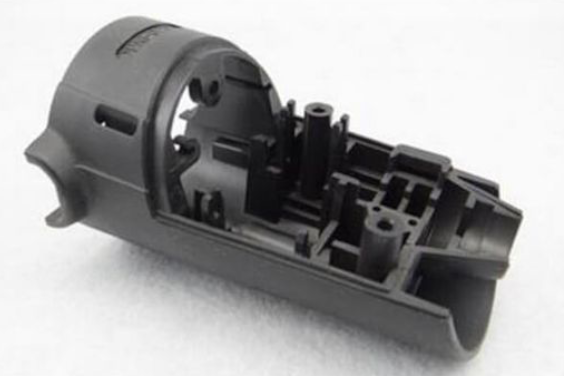

Insert Molding Process

Insert molding process is the one where the preformed part is loaded into a mold which is then overloaded with plastic to create the final product.

Benefits of insert molding process are:

- It reduces labor cost

- It reduces assembly cost

- It improves component reliability

- It increases the design flexibility

- It reduces the size and weight of the part

Application of plastic injection insert include screws, studs, contacts, clips, spring contacts, pins, surface mount pads, etc.

2 Shot Molding Process

Two-shot molding processes are also known as dual-shot, double-shot, multi-shot, and over-molding. It is a process in which two different plastic resins are molded together.

Benefits of two-shot molding process include-

- Part consolidation

- Improvement in efficiency

- Improvement in quality

- Complex molding

Applications of two-shot molding processes include complex, multi-colored plastic. It serves in various industries including lawn, agriculture, etc.

Applications of Insert Stretch Blow Molding Process

The application of insert stretch blow molding process are:

- Coloured and transparent bottles such as that of sauce.

- Toilet cleaners

- Liquid detergent and hand wash bottles with handles

- Personal care products

- Room fragrance

- Multiple components for air fresheners

- Toilet fresheners

Wrapping up

The injection stretch blow molding process is used in the manufacture of different types of plastic materials, mainly bottles. They are used mostly because they provide benefits combined with the blow molding and injection molding process. Durability and the preciseness of the finished product, for one, are considered the major benefits.

Owing to that, this injection stretch blow molding process offers a great product with low production cost as well. The applications are numerous as well. For a good injection molding service, you can contact RYD tooling.