Insert Molding Process Step by Step

It is dangerous to make use of components after they’ve been manufactured without encasing them with plastic. It’s essential to encase these components to make

Share

Share

Clear plastics are the most widespread type of packaging material in all sectors around the world. The reason is simple, the ability to see what is packaged clearly inspires confidence in consumers; they are able to tell the condition of the contents before committing their money. For this reason, it is important to know how clear plastic molding is undertaken and, most importantly, the materials that are used in their manufacturing.

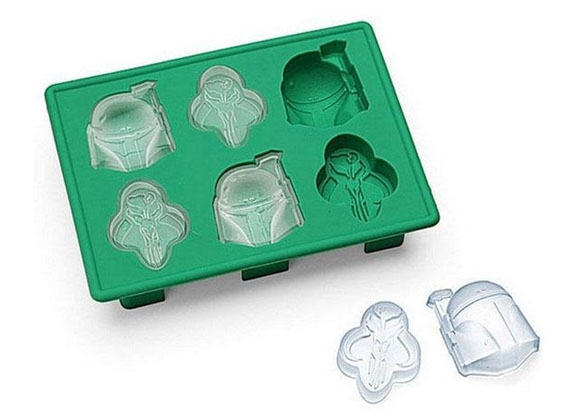

Source: Pinterest

Acrylonitrile Butadiene Styrene is considered to be one of the toughest plastic materials on the planet that comes with many benefits. This makes it a very popular raw material used by a number of manufacturing companies. The materials offer very high resistance against impact, and this makes the best solution for food packaging from juices, snacks, among many others. The best part of this material is that, despite the many good properties and features, it is extremely cheap to make and can be recycled later on for reuse without losing any of its redeeming features.

Source: Pinterest

Acrylic is another widely used material that comes in a transparent form with varying colors, which can be added to it to make it more unique. It is a thermoplastic homopolymer that is better known as plexiglass and has very high resistance against impact. Acrylic dates back to 1938, when it was first discovered by the Rohm and Haas company. To date, there’s no other type of plastic that’s as clear as acrylic. In the modern world, acrylic is used for a number of tasks like the creation of lenses, windows, security barriers, medical devices, LCD screens, among many others.

Source: Pinterest

K-Resin is another clear polymer that is best known for its ability to combine flexibility and impact toughness and gloss. It is mostly used in the making of packaging materials as well as the manufacture of toys and all the special medical equipment. K-Resin has been used for over 40 years now, and better versions of it are being created every year to further improve its qualities and usage. Like most of the other materials, K-Resin has good longevity and can be recycled many times over, making it a cost-effective material to use for manufacturers.

Source: Pinterest

NAS is another highly regarded material that produces sparkling products used for a number of tasks, both domestic and commercial. It has a very clear appearance which is also challenging, easy to handle, and has enough stability to handle any type of material. Some of the key features that make NAS such an excellent raw material for molding processes include its low density, it can be sterilized, and is approved as safe for a number of important jobs. NAS is commonly used in the manufacture of cosmetic jars, reusable drinkware, toys, medical devices, among many others.

Source: Pinterest

When it comes to availability and ease of processing, then Nylon is king. It is a generic variation of the synthetic polymer family, and it has a silk-like appearance. Nylon can be melt-processed into a number of variations, from solid forms that can be used to make super hard products to paper-thin and transparent materials used for packaging food and other things. Nylon has been commercially produced since 1927, and it has undergone a lot of changes over the years to become one of the most versatile products around.

Source: Pinterest

Polycarbonate is a naturally transparent and amorphous thermoplastic that can be made to take on any shade of color for that extra appeal. The material allows for the transmission of light with the same capacity as glass, and for this reason, it is used to make products that require high impact resistance and have the right transparency that allows people to see the contents inside the packaging or the jar. Polycarbonate is mostly used in the making of lenses for common glasses, ski goggles, welding goggles, among many others. They have the best protective features, and they last for very long.

Source: Pinterest

Also called polyaryl sulfones, this is a special class of plastic material that is engineered to have a high thermal, transparent, oxidative qualities that make it easy for it to be molded and extruded into any shape when exposed to the right amount of heat. This also gives the material a high tensile strength which makes it the best raw material for making packaging material as well as other tough products used in intensive activities. Polysulfone can be sterilized and used for packaging food and medicine, and at the same time, it can be found inside batteries as internal casings, among many other applications.

Source: Google

Polystyrene is another highly versatile plastic polymer that is used in the manufacture of a lot of consumer goods. It is especially ideal for making hard and solid objects that are either transparent or translucent. At the same time, they are compatible with dyes and can be mixed with dark colors to make opaque materials. Polystyrene is derived from expanded polystyrene, which comes with very reliable insulating properties, which explains why it is widely used in making electrical components. A majority of products that benefit from polystyrene include home appliances, automobile parts, roadway stabilization systems, among many others. It is also highly preferred in the food packaging industry due to the toughness that makes it hard for them to break or tear apart.

There are countless other plastic materials that can be used for making clear plastic moulds. Each of them comes with their own unique properties that make them ideal for creating certain objects. As time goes by, modifications are being added to these materials to make even better and tougher ones. For more information, check out our website to learn some more about clear plastic molding.

It is dangerous to make use of components after they’ve been manufactured without encasing them with plastic. It’s essential to encase these components to make

Transparent plastic is being used in virtually every industry and this is because of its capacity to allow you see through and its ease of

Plastic is a common material used in the production of objects that can be used in homes, the automobile industry, and virtually all sectors. It

Basically, there are two kinds of plastics – thermoplastic, and thermosets. But the majorly talked about kind is the thermoplastic because of its versatile and

+86-755-8524 1121

marketing@rydtooling.com

No. 2, HongKan 1st Road, YanChuan Community, YanLuo Street, BaoAn District, ShenZhen City, China. Post Code 518105.

Subscribe to our newsletter to get manufacturing news and updates!